- The new CLA is the first model to feature MB.OS in series production.

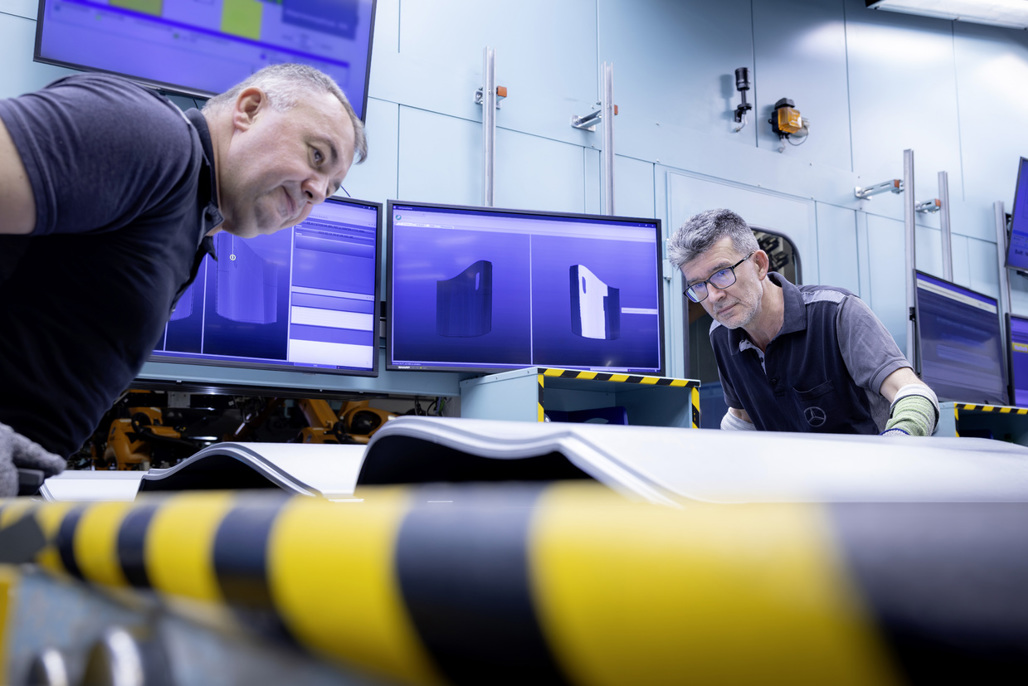

- Mercedes-Benz’s Rastatt plant uses AI and digital twins for efficient manufacturing.

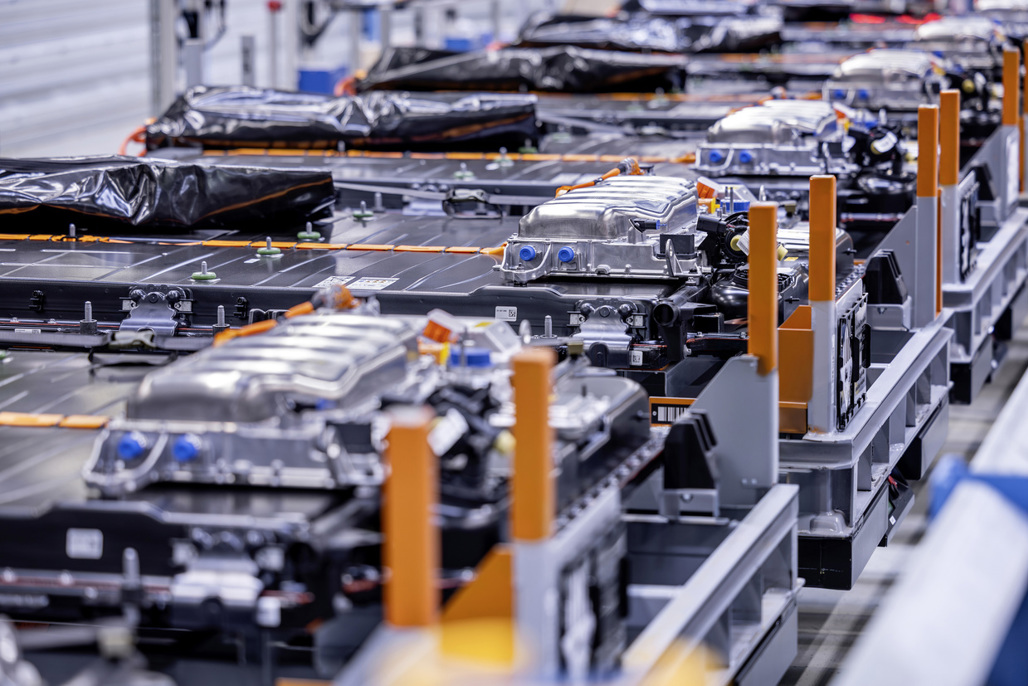

- Batteries, drive units and body components are all sourced within Germany.

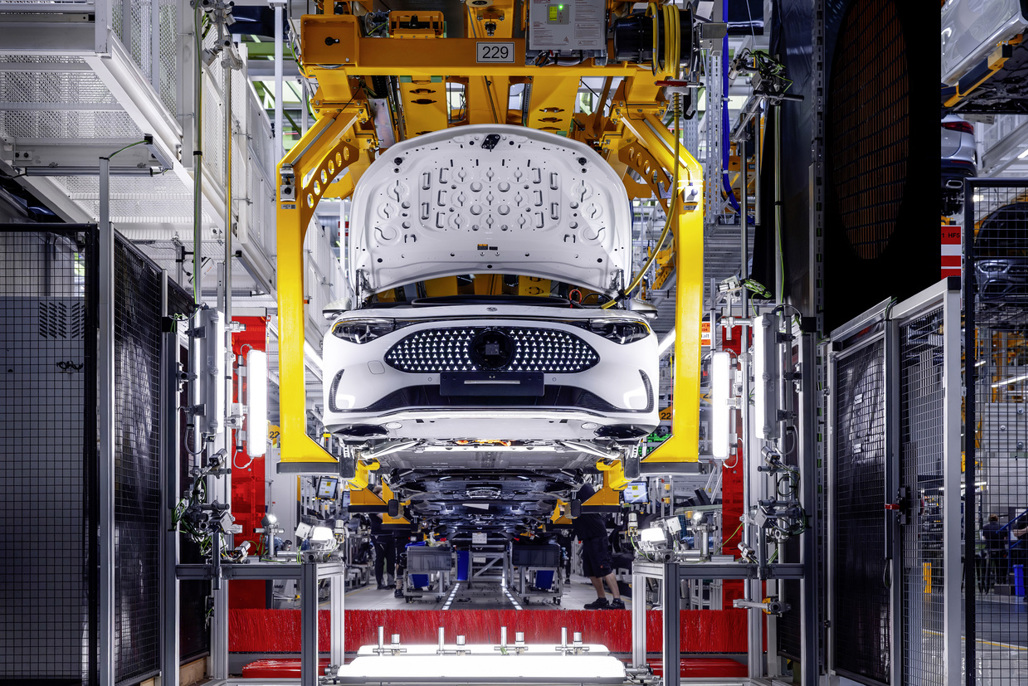

The next-generation Mercedes-Benz CLA has officially entered series production at the brand’s Rastatt plant - marking a pivotal leap in how the German giant builds its cars.

The all-new CLA is the first model to integrate MB.OS, the brand’s in-house operating system, into full-scale production, wrapped in a “Digital First” philosophy and supported by AI and simulation tech.

Batteries, bytes and bots

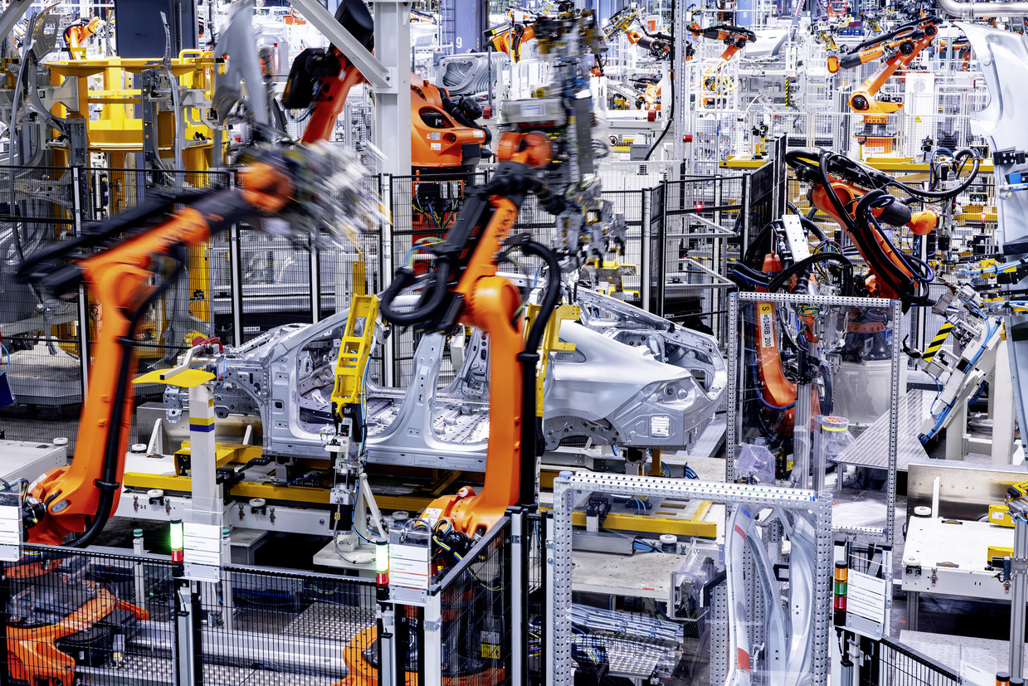

Unlike its predecessors, this CLA aims to be more than just another stylish four-door coupe - Mercedes says it's the spark of a new electric-first generation. It also rolls off the same flexible line as hybrids and combustion models, thanks to a speedy remodelling of Hall 4.0 using digital twin simulations. That virtual prep shaved down construction time and cost, helping the plant go from plan to production in just weeks.

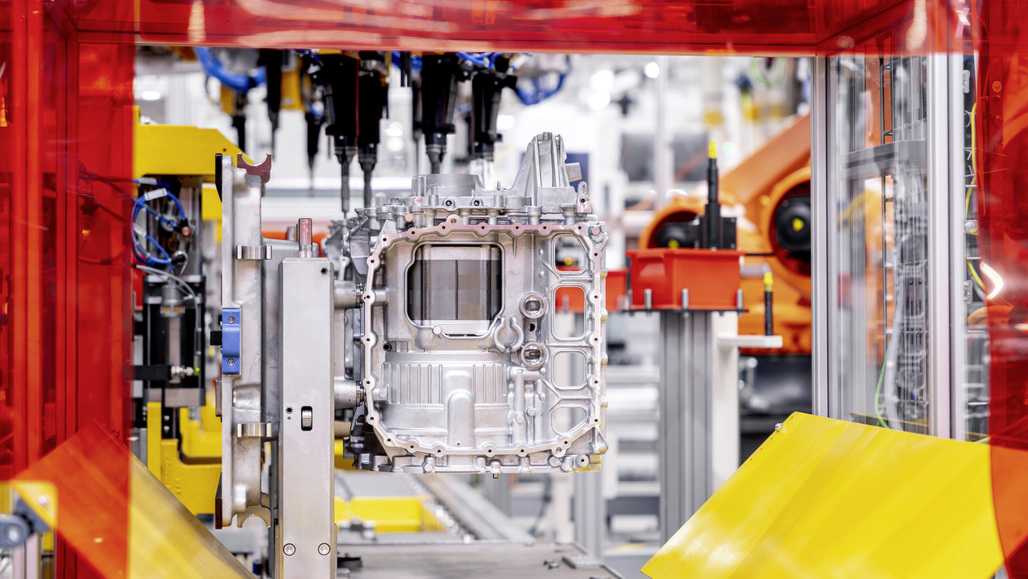

The CLA’s electric bits are all local. Drive units and axles come from Stuttgart-Unterturkheim, batteries from Kamenz and body components from Kuppenheim.

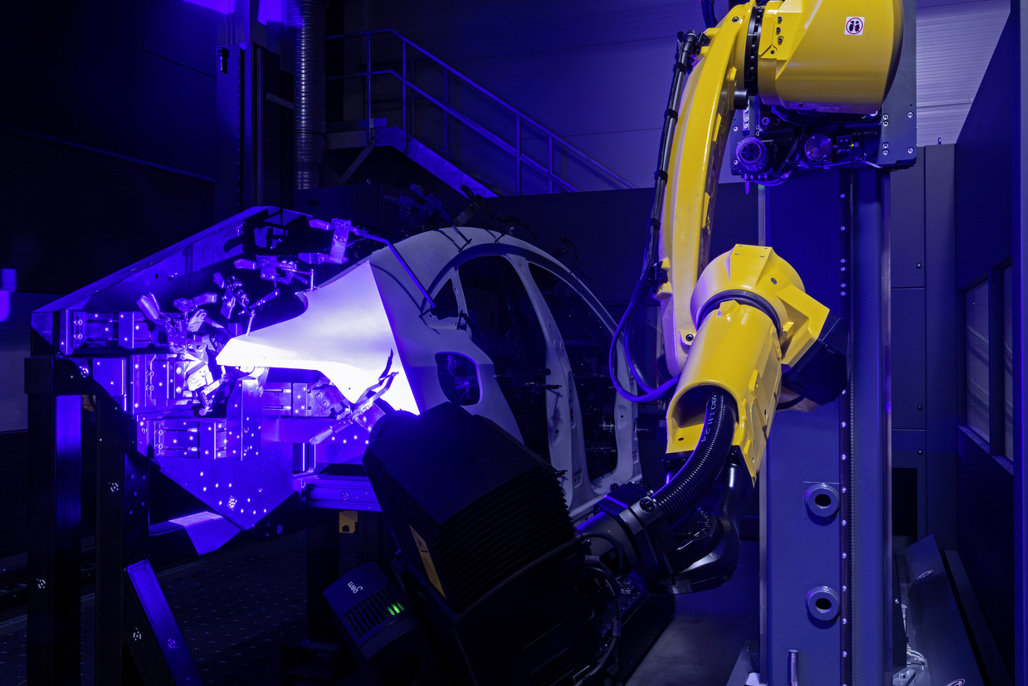

The fully integrated supply chain feeds into a production line that uses AI (not humans or programmable controllers) to monitor top-coat painting, which Mercedes-Benz says has cut energy use by 20%.

Built for the future, not just the present

The Rastatt plant itself is a showcase of the brand’s ambitions. It's powered entirely by green electricity, with solar panels generating up to 8MWp. Further reductions in energy use are thanks to heat recovery systems and new-gen robots.

Mercedes-Benz is even piloting a large-scale organic battery storage system on site - another nod to scalable, sustainable manufacturing.

Transport emissions are on the hit list too. Finished CLAs are shipped 600km to Zeebrugge via electric trucks, while local recycling loops through the nearby Kuppenheim plant, which handles battery and metal scrap reprocessing.

More than a new car

"This CLA marks the start of a new era," said Mercedes-Benz Group CEO Ola Kallenius. “The best guarantee for the long-term success of electromobility is top-of-the-range products like the CLA” - adding that conditions must stay competitive to keep such models ‘Made in Germany’.

Production will expand to Hungary and China in due course, but Rastatt remains the launchpad, carrying not just the CLA, but the company’s ambition to electrify with precision - and a whole lot of code.