BMW is taking a bold step into the future of automotive manufacturing at its Spartanburg plant in South Carolina.

The German automaker has partnered with Figure AI, a startup founded in 2022, to introduce humanoid robots into the manufacturing process.

This move could revolutionise the way cars are built and set a new standard in the industry.

The rise of robotic assistance in auto manufacturing

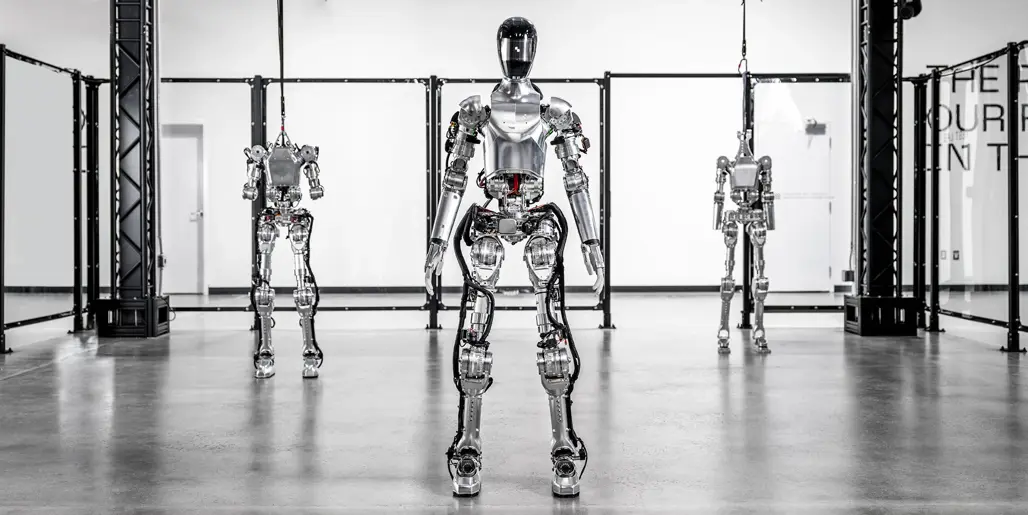

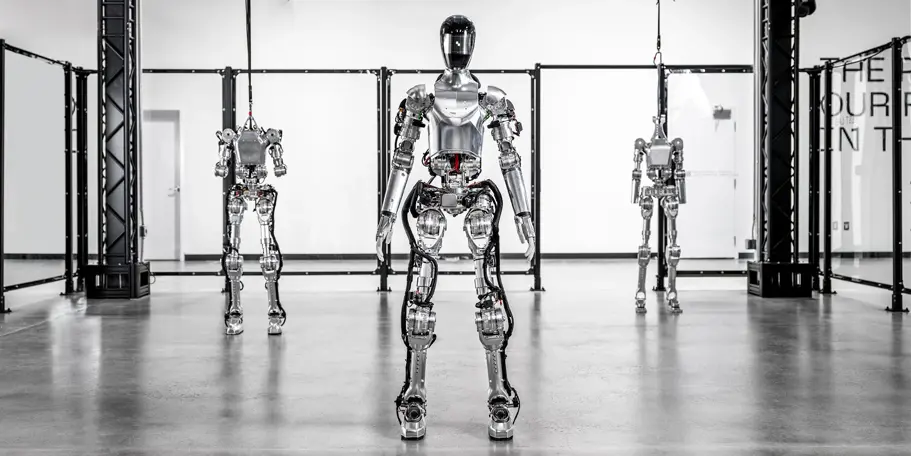

At the heart of this technological leap is a humanoid robot developed by Figure AI. This robot stands 5'6" (1.67m) tall, weighs 60kg, and boasts a payload capacity of nearly 20kg.

It's designed to operate alongside human workers, ensuring safety and efficiency in the plant's operations. BMW's Spartanburg facility, known for producing popular models like the BMW X3, X5, X6, X7, and XM, is an ideal proving ground for this innovative technology.

The robot's deployment marks the first commercial deal for Figure AI, showcasing the rapid progress the company has made since its inception.

In less than two years, Figure AI has developed a working humanoid with dexterous manipulation capabilities and landed this significant deal with one of the world's leading carmakers.

A cautious yet optimistic approach

While the exact number of robots to be deployed remains undisclosed, Figure AI's CEO Brett Adcock has indicated that the rollout will begin with a small number and scale up based on performance. T

his cautious approach reflects the industry's mixed experiences with automation, including recent equipment malfunctions and the underwhelming debut of Tesla's Optimus robot.

Adcock remains confident, however, stating, "We have designed the robot to be safe next to humans. Working with BMW on automation in a manufacturing facility is a huge validator for us in the space."

Potential impact and industry implications

The integration of these robots marks a significant shift in automotive manufacturing. If successful, they could enhance efficiency and speed in the production process.

However, there's also a risk of unforeseen complications leading to recalls. The outcome of this venture is eagerly anticipated, not just by BMW and Figure AI, but by the entire auto industry.

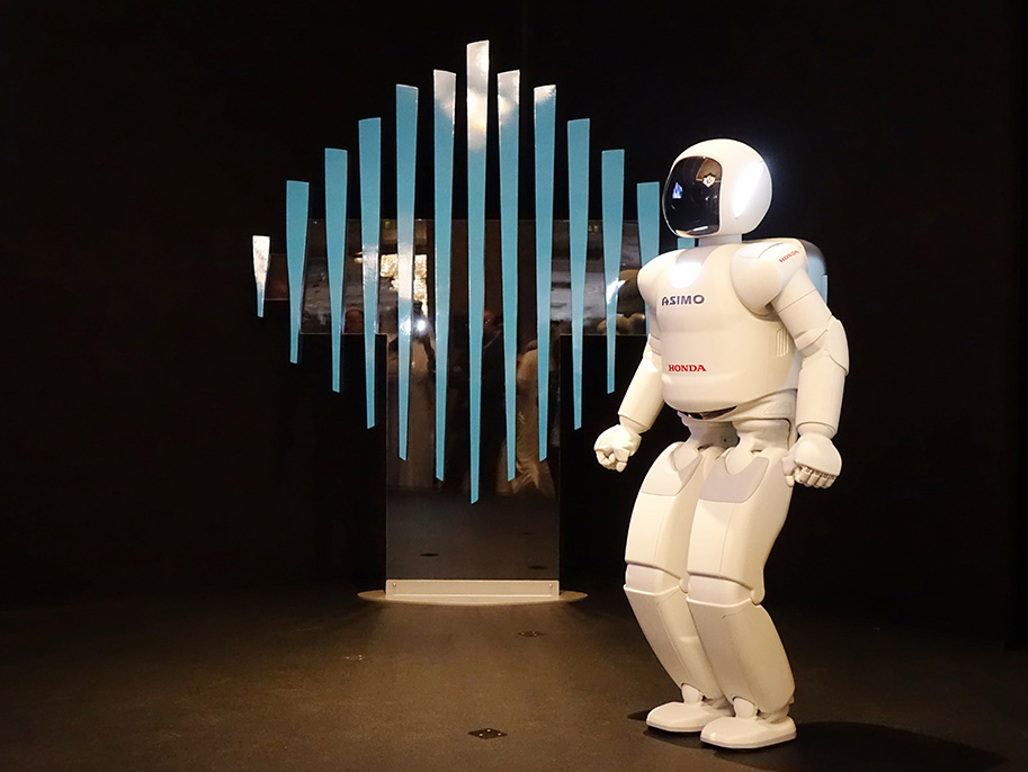

Drawing parallels with past innovations

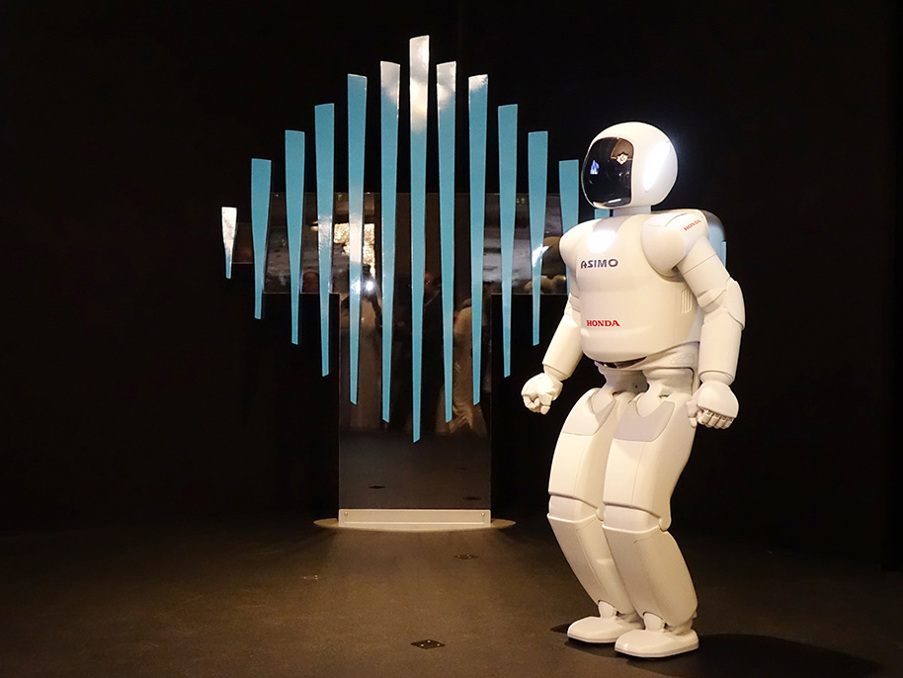

This move by BMW and Figure AI echoes the journey of Honda's Asimo, the first advanced humanoid robot. While Asimo never found practical application in the industry, it paved the way for future innovations like the robots being introduced at Spartanburg. BMW's plant, already the largest automotive exporter in the US by value, is set to make another mark in the history of automotive manufacturing.

BMW itself is no stranger to robotics. The company won a 2021 Robotics Innovation Award for its subsidiary IDEALworks, which developed the Smart Transport Robot STR for intralogistics work in automotive factories.

The company's Spartanburg facility already utilizes over 2000 high-tech precision robots for various manufacturing tasks, showcasing BMW's commitment to innovation and digitalisation.