The biggest criticism of the new-generation BMW-Mini is arguably that it's too large, complex and luxurious - a long way from the minimalist roots of the iconic original.

How much dramatic irony there is in the new Mini Strip created in partnership with British designer Paul Smith is not clear (we're going to say none), but the one-off car is a pretty interesting exercise in the carmaker's stated themes of "simplicity, transparency, sustainability".

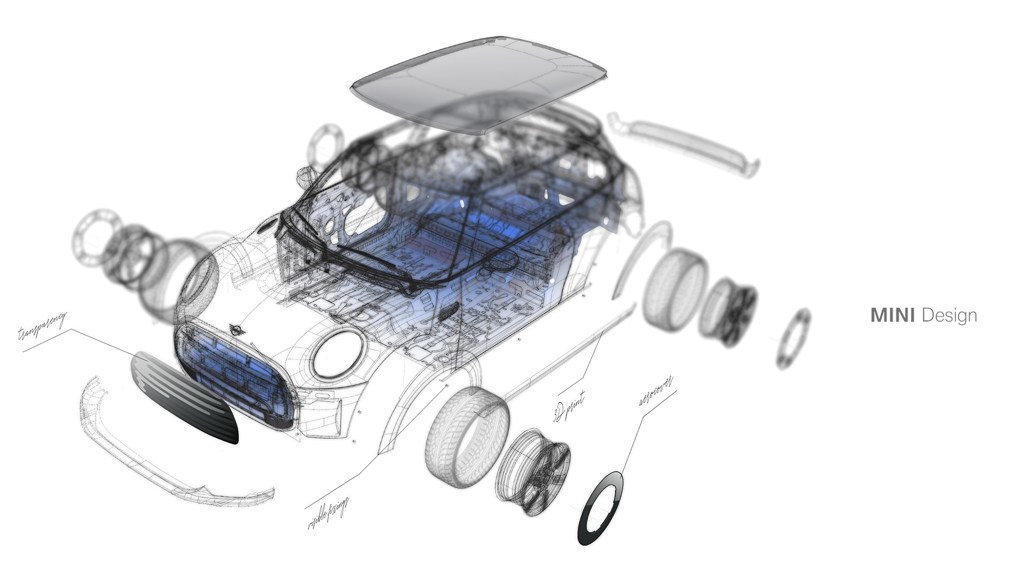

The design process began by completely stripping down a Mini Electric and reducing it to a bare structure. Only then were the elements that Smith viewed as absolutely necessary defined and implemented.

“I’m incredibly grateful for the opportunity to rethink the iconic Mini," says Smith. "I know and love the existing car, but by respecting the past and looking to the future we have created something very special. I think we have created something truly unique, by going back to basics, reducing things down and stripping the car.”

Raw materials are a deliberate part of the exterior design - the body was left in its unfinished state with no coloured paint applied, but instead just a thin film of transparent paint to protect against corrosion. Grinding marks from the factory have been left intact on the galvanised steel panels to identify the car as a functional object: this effect is dubbed “the perfect imperfection” by Smith.

To view all Mini models listed on DRIVEN, click here

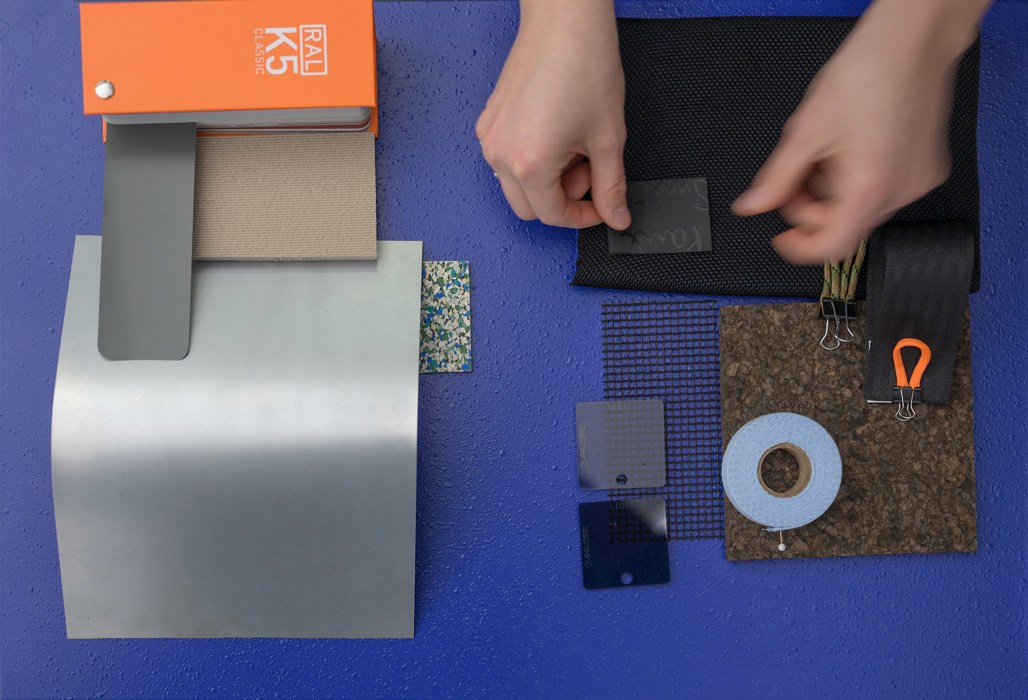

Some parts have been 3D-printed from recycled plastic and their basic material qualities have been left exposed - like the metal panels. Bicycle enthusiast Smith provided the inspiration for the visible screws in the add-on parts, which show how simple dismantling would be and how easily the vehicle could be reincorporated into the raw-material cycle at the end of its service life.

The blanked-off radiator grille and wheel covers help to reduce drag, increasing its theoretical range. Both are made from recycled Perspex. Recycled Perspex was also used for the large panoramic roof that gives outsiders a view of the bare structure inside.

Open the doors and there's signature Paul Smith stripes in five colours; the charging flap adds a splash of neon green when opened, while the engraved drawing of an electric plug on the flap is Smith’s own work.

All interior trim parts have been omitted, with the exception of the dashboard, topper pad and parcel shelf, turning the bodyshell into the dominant visual feature of the cabin.

It has been coloured blue at the request of Smith - an obvious reference to a limited-run Mini he helped create in 1998 in a bespoke shade of blue (including the alloy wheels).

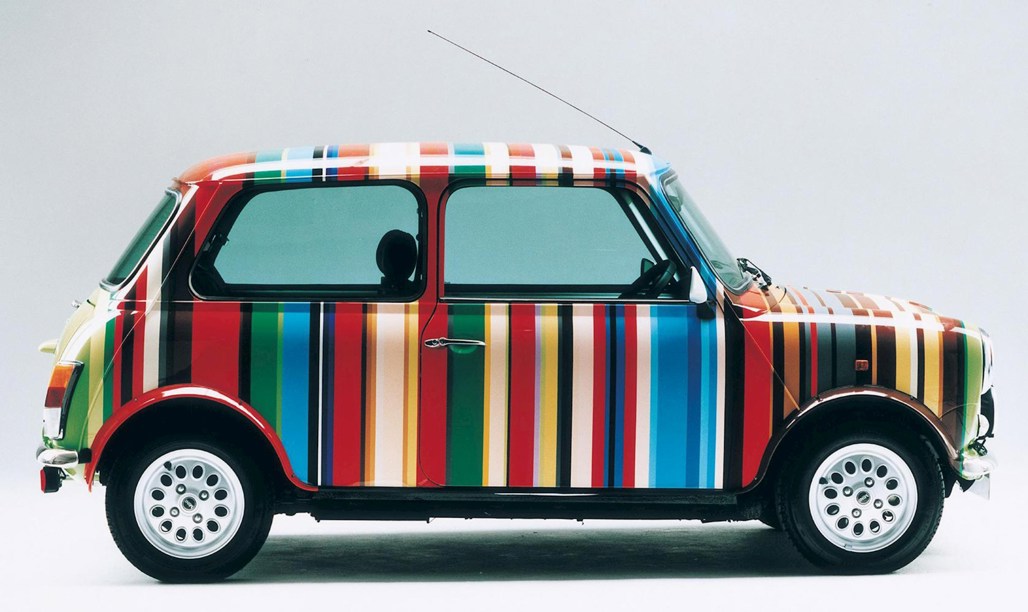

Smith created another one-off Mini in 1999 to celebrate the car's 40th birthday. The exterior was finished in his signature multi-coloured stripes.

The Mini Strip dashboard consists of one large, semi-transparent section with a smoked-glass finish. There is no Mini-signature centre instrument, leaving the driver’s smartphone to take centre stage instead. It is placed where the centre display would normally be, connects automatically to the car and becomes the media control centre.

The seats are upholstered in a knitted fabric. The mono-material design for the seat coverings means they are fully recyclable, including the piping. The floor mats are made from recycled rubber, with their distinctive pattern a by-product of the recycling and manufacturing process.

The dashboard topper pad, door shoulders and parcel shelf are made from recycled cork (shades of Mazda's MX-30) which doesn’t contain synthetic binding agents. Due to cork’s recyclability and its status as a renewable raw material that actually “fixes” carbon dioxide during its production, there is potential for reducing greenhouse gases. Another positive side effect of knitted fabric and cork is that they are both open-pore materials that enhance interior acoustics.

The steering wheel has been reduced to the most essential functions. Its rim has been wrapped in handlebar tape, like a road bike. Three aluminium spokes connect the rim to the steering wheel’s impact absorber, whose mesh covering makes it possible to see the airbag behind.

As on the outside of the car, there are visible screws showing how easy it would be to dismantle the steering wheel at a later date and reuse the aluminium.

The door panels are made from the same mesh material that covers the airbag, enabling the door structure to be clearly seen behind the mesh panels, which are held within a frame. The transparency of the knitted mesh changes according to the angle of view. The pull handles in the door shoulders are made from climbing rope.