The latest step in BMW Group’s green evolution has arrived in the form of the Mini Concept Aceman, the brand’s first fully electric crossover.

Mini already offers the Electric Hatch and a plug-in hybrid electric vehicle (PHEV) version of the Countryman, but the Aceman points to a new design and technology path for the brand.

Aceman stands for Mini’s all-electric future, with an electrified go-kart feel and strong focus on a minimal environmental impact. But that green ethos isn’t merely down to a zero-emissions powertrain. There’s much more to sustainability than what doesn’t come out of the exhaust pipe.

The Aceman’s design language, called “charismatic simplicity”, also embodies a sustainable manufacturing approach. The look is pared back and the car is devoid of chrome, while the interior concept also eschews leather in favour of more sustainable materials.

Mini will be a pure-electric brand by 2030, but BMW Group as a whole is also focused on electromobility expansion and an ambition to transition to a carbon-neutral business while maintaining maximum powertrain choice for customers.

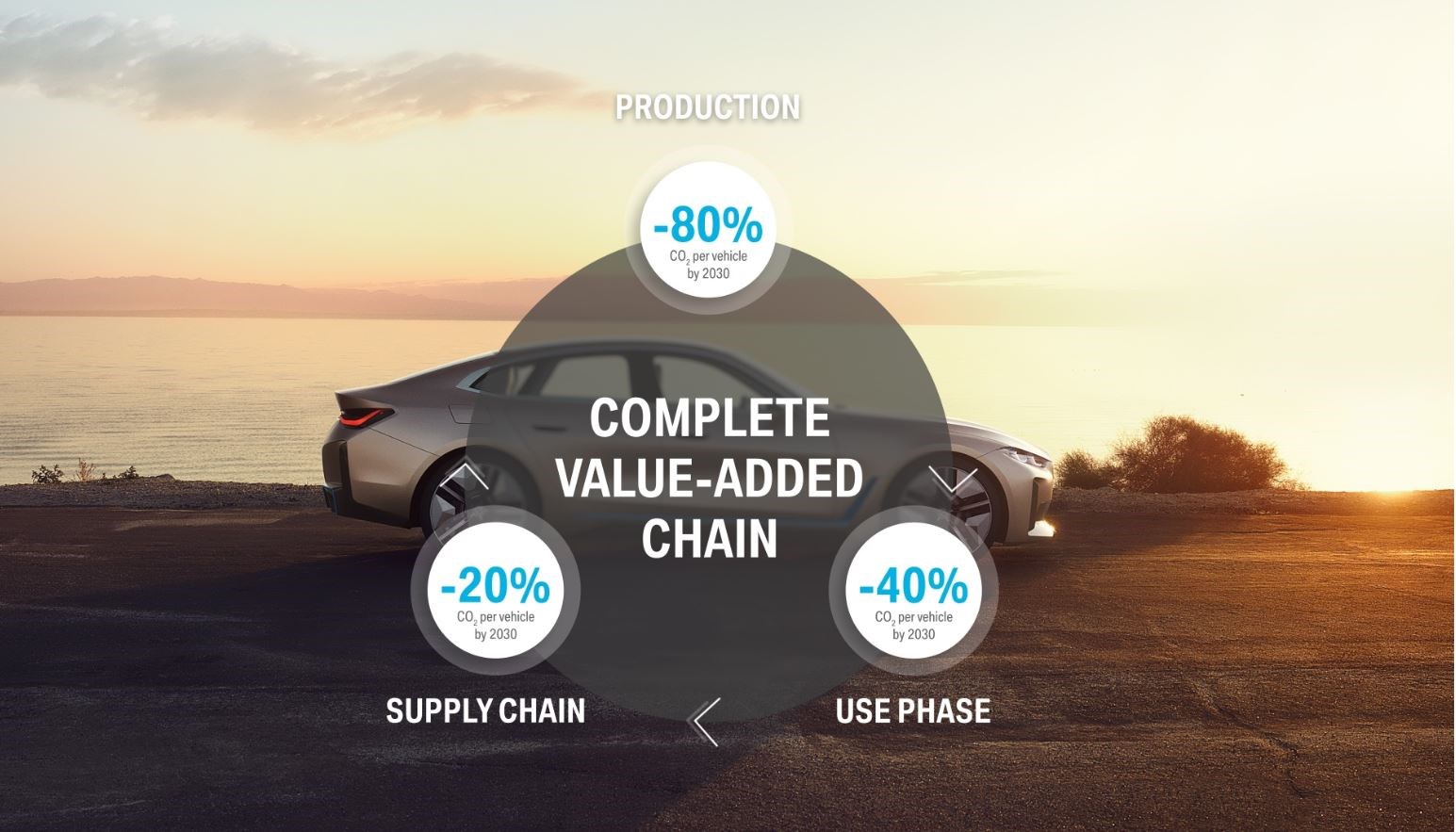

Compared with 2019 CO2 emissions, BMW is targeting a 20 per cent reduction in the supply chain by 2030, and an 80 per cent reduction per vehicle, as a “firm and verifiable goal”. It has committed to total carbon neutrality by 2050.

Verifiability is key to making a real difference. BMW is also a member of the Science-Based Targets Initiative (SBTI) and signed the Business Ambition for 1.5-degree pledge ahead of the UN Climate Change Conference in 2021.

“How companies are dealing with CO2 emissions has become a major factor when it comes to dealing with corporate action,” says Oliver Zipse, chairman of the Board of Management of BMW Group.

“The decisive factor in the fight against global warming is how strongly we can improve the carbon footprint of vehicles over their entire lifespan. This is why we are setting ourselves transparent and ambitious goals for the substantial reduction of CO2 emissions. These are validated by the SBTI and will deliver an effective and measurable contribution.”

True sustainability starts before the first component of a car has been created and covers all elements including materials selection, supply chain, use phase and end-of-life recycling.

BMW’s i Vision Circular concept vehicle embodies the carmaker’s future focus on a “circular economy” – the aim of keeping raw materials in the cycle for as long as possible.

It demonstrates how a vehicle can be produced entirely from secondary materials. Current BMW production models already average 30 per cent and the company aims to increase that figure to 50 per cent.

The forthcoming Neue Klasse range, going into production around 2025, represent the next milestone vehicle line-up for BMW. These models will be based on a bespoke pure-electric platform called New Cluster Architecture (NCAR), which has been created around three core elements: electric, digital and circular.

The maker is promising “typical BMW sheer driving pleasure, an emotional design, and a powerful and highly efficient drivetrain”.

But just as importantly for its new core model, it will achieve a new level of sustainability through the premise of “secondary first”, using recycled materials wherever possible.

This double aim of delivering an engaging product that is also sustainable across the entire value chain underlines an approach that is not new to the BMW Group but which has never been more relevant: the delivery of solutions that can stir emotion while doing it in a responsible, forward-thinking manner.