EXCLUSIVE: WE’RE IN MUNICH FOR A LOOK INTO BMW’S FUTURE

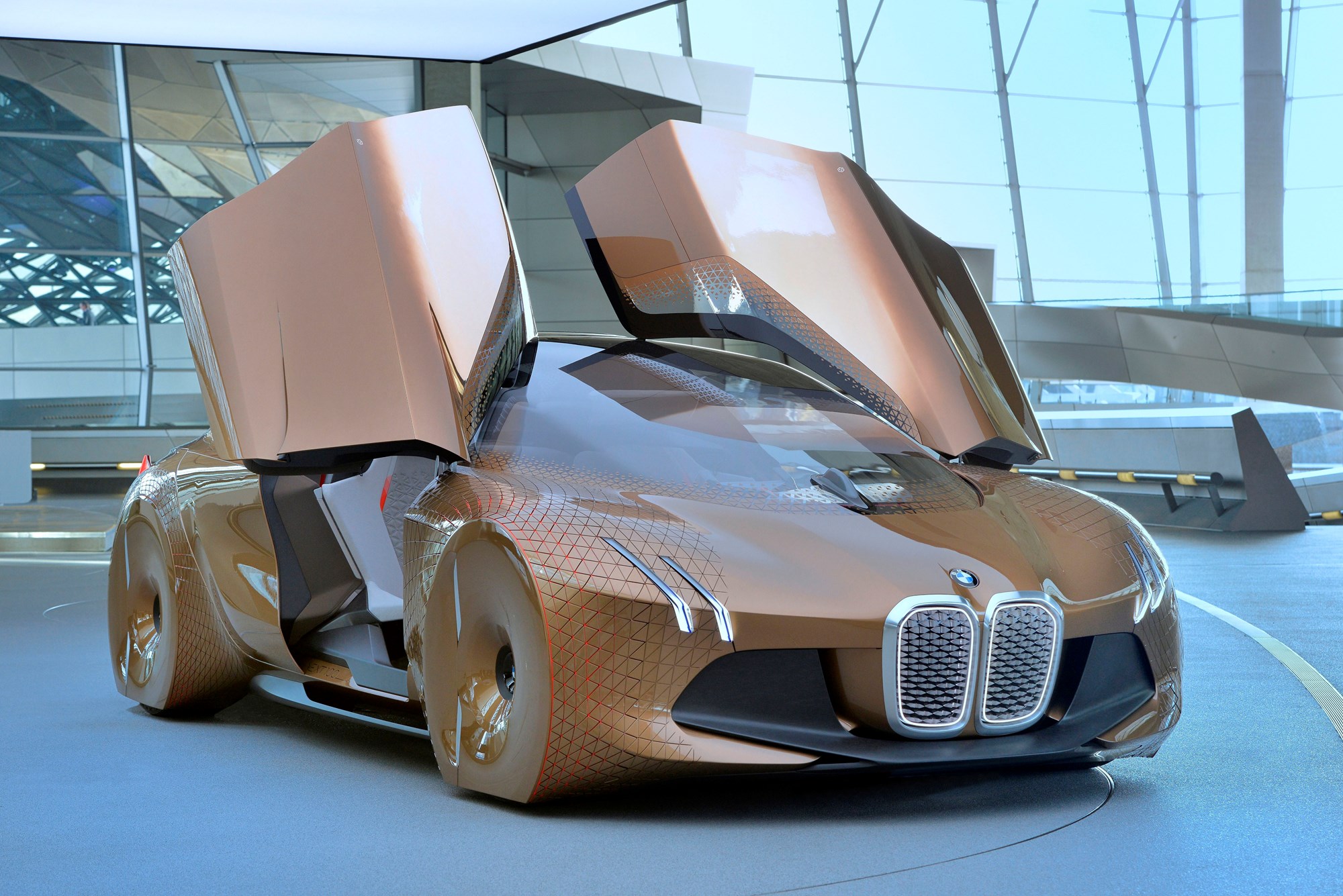

It took BMW Group’s designers in Munich a year to perfect a 20mm diamond panel for a concept vehicle to be revealed at the company’s centenary.

But that small panel was an integral part of the concept vehicle that BMW called Vision Next 100, and was revealed at the Olympic Hall last month, as part of the company’s centenary.

While technically the company didn’t start making vehicles until 1923 with the R 32 bike, March 7 marked the anniversary of the founding of the company Bayerische Motoren Werke (Bavarian Motor Works).

Harald Kruger chairman of the board of management of BMW AG

Harald Kruger chairman of the board of management of BMW AG

BMW Group’s chairman Harald Kruger told a press conference before official celebrations, that the 100th anniversary was looking towards the next 100 years of motoring, and mobility for 2030 and beyond.

The Vision Next 100 would be followed by concept vehicles from the three other brands in the group — Mini, Rolls-Royce and Motorrad — over the next few months.

BMW Group’s head designer, Adrian van Hooydonk, said the Mini concept car to celebrate the centenary would be revealed in June with the theme “Every Mini is My Mini”, while for the first time in its history, Rolls-Royce has created a concept vehicle, with the title “Grand Sanctuary”.

The motorbike brand, Motorrad, would show its concept vehicle in October with the slogan “The Great Escape”.

The Vision Next 100 concept car had a choice of driver-controlled or vehicle-controlled functions with a clear dash, information reflected on to the front window (including the ideal drive line and hidden objects), plus instead of a steering wheel, something van Hooydonk admitted to the press conference didn’t have a name.

“Maybe a steering furniture?” he suggested.

A few hours after the press conference, the Vision Next 100 concept car was driven on to the stage in front of VIP guests, BMW Group executives, and the international media, including Driven.

A few hours after the press conference, the Vision Next 100 concept car was driven on to the stage in front of VIP guests, BMW Group executives, and the international media, including Driven.

Production at the company’s factories stopped during the hour-long centenary event and BMW said more than 32,000 employees watched the live stream of the ceremony.

The next day Driven interviewed BMW Automobiles’ head of design, Karim Habib, and Vision Next 100’s project leader, Julia de Bono, at the company’s famous BMW Welt (the large building next to the company’s headquarters that displays all the vehicles from the brand).

While Driven had inspected the Vision Next 100 at the Olympic Hall just after the ceremony the evening before, in daylight and in BMW’s modern building, the car looked more like a bronze sculpture rather than a working automobile.

But when it came to the brief for BMW’s design team, it was to create a vehicle that we’d be driving in 20 years.

While the automotive industry looks five to 10 years ahead, two decades brings new challenges for designers as technology is moving so fast.

The team had to identify trends and technological developments that would impact BMW in 20 years’ time, such as 4D printers.

But it was 3D printers that would be essential in creating the diamond panels that would be standout aspects of the car.

Forming what BMW’s designer classified as Alive Geometry, the rows of the diamond shapes replaced the wheel arches and hid the tyres.

At the helm of the Vision Next 100.

At the helm of the Vision Next 100.

But, as the tyres move, the diamond-shaped panels expand and move with the wheels.

De Bono demonstrated the feature to Driven by having an assistant turn the “steering wheel” (or steering furniture) via a touchpad.

The Alive Geometry is like an elastic skin over the tyres, and not only are visual dynamic were made to help with the aerodynamics of the vehicle.

De Bono told Driven that it took a team of seven or eight people a year to make the “make this little thing of the exterior”.

“It was very, very complex. It looks very simple from the outside but it has taken a lot of thought and a lot of sweat.

“There’s a lot of computing, a lot of model-making, and it was very challenging.”

The inspiration was having to cover the wheels for aerodynamic reasons.

“You have to have some kind of moving shapes, so you have a few possibilities, but 4D printing is a very modern [technique] and we wanted to use the tooling possibilities to make the car of the future.

“There were many solutions but this one is the one that we preferred in this case.”

The Vision Next 100 concept car was made from aluminium but de Bono said in the future she could “imagine strong plastics would make the panels”.

The concept car was the length of a 5 Series sedan, but had the interior cabin space of a 7 Series. For head designer Habib, the concept vehicle is “your co-pilot, your companion, and a type of personal assistant”.

“You get a huge amount of information already and in the future there will be even more of this,” he said.

Inside the Vision Next 100 concept car, the seats and door panels combine to form a single unit so the driver and passengers can turn to face each other.

The rear view of the concept vehicle

The head-up display would also work as a personal monitor with for example, images projected on to the windscreen.

Although van Hooydonk and his boss Kruger wouldn’t be drawn on what the powertrain for such future cars would be, with BMW’s i8 as inspiration, it would make sense that the Vision Next 100 would be an electric vehicle.

● For more on BMW’s centenary and the Vision Next 100, go to driven.co.nz